The brakes start life as raw materials.

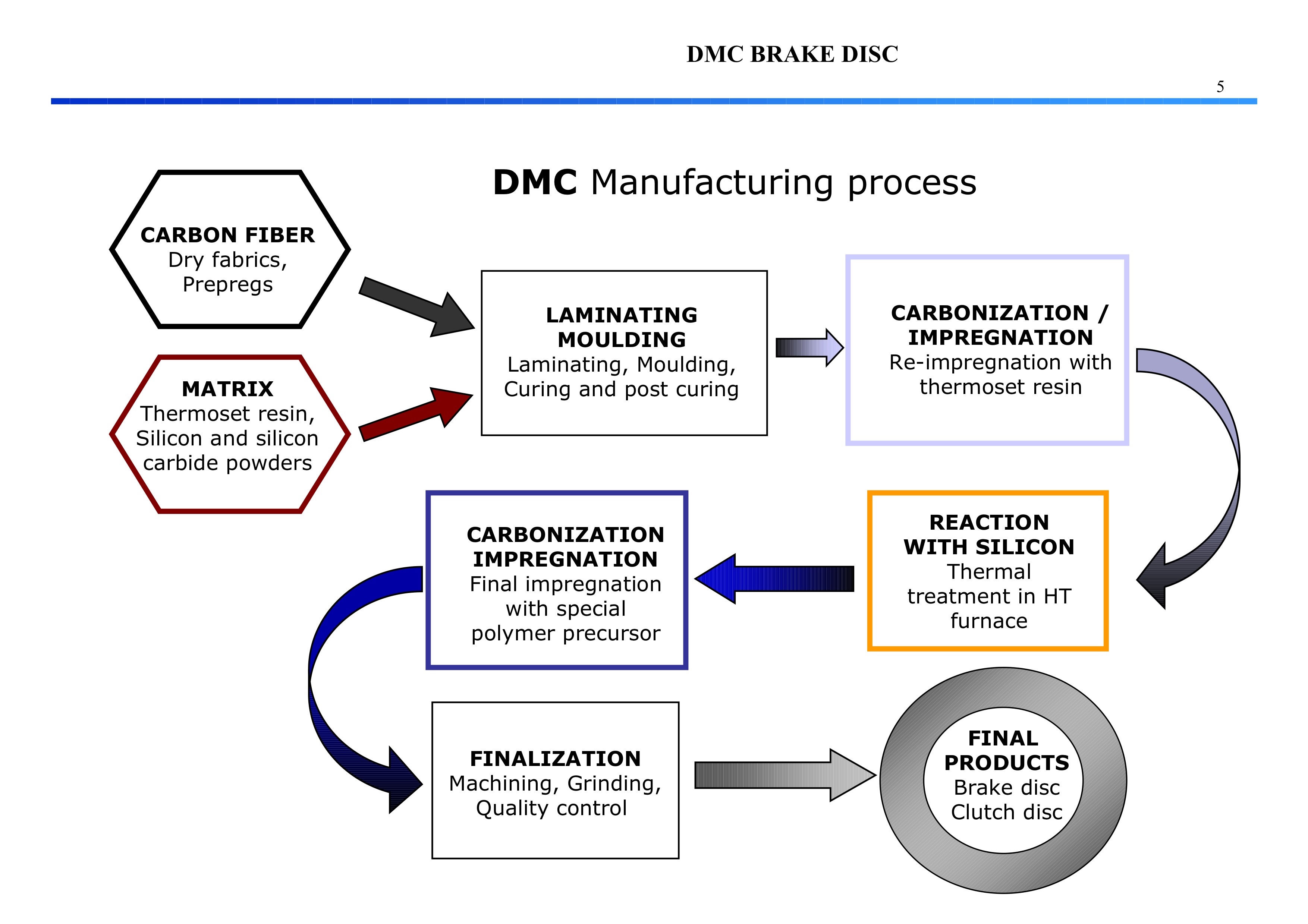

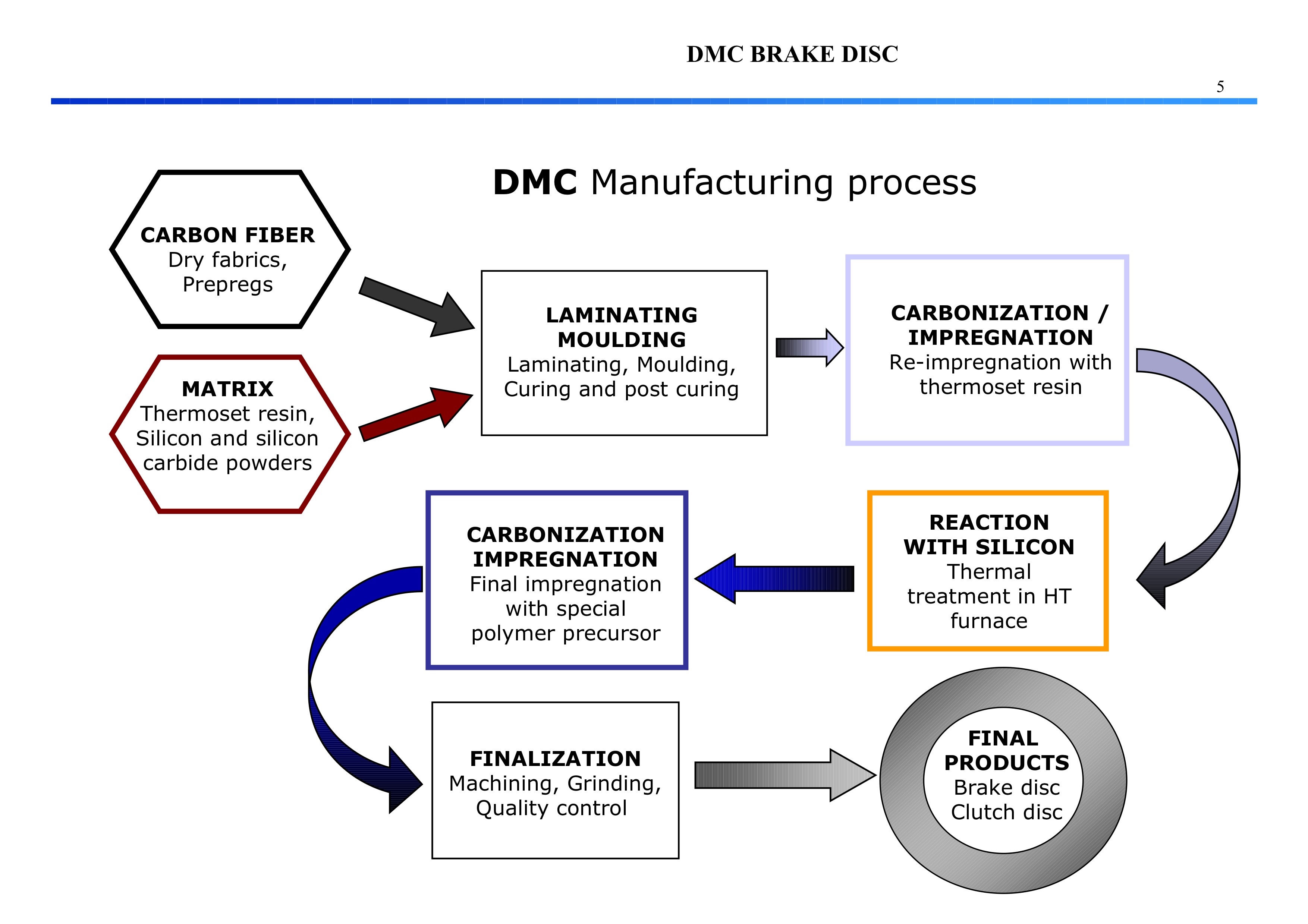

Ceramic disc brakes manufacturing process.

Manufacture process of carbon ceramic brakes.

Basic disc shaping operations fig.

The manufacturing details of ceramic composite brake discs.

To produce carbon ceramic brake discs we use carbon fibers which are given a special protective coating and then cut into short fiber sections of defined thickness and length.

As they head through the production process machines pour the mixture into a mold the shape of.

The carbon ceramic brake disc has a production process over approximately 20 days.

A filling the mold b inserts the aluminum cores c pressing the ingredients together d extracting the disc ring e preparing for siliconization.

The manufacturing method used in production of brake discs is the metal casting process and to be more specific it is the permanent mold casting process that takes place in the production of these brake discs that usually gives out a good surface finish for the end product 2.