Although only implemented by aluminum foundries since the late 1970s ceramic foam filters are increasingly being used to prevent nonmetallic materials from entering the mold cavity resulting in premium quality castings demanded by today s market.

Ceramic foam filter technology for aluminum foundries.

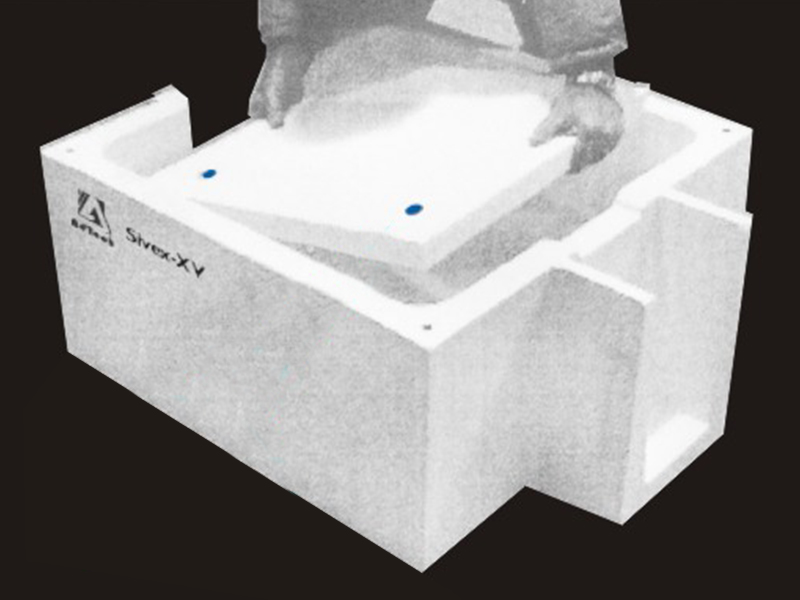

Picture 3 gas heated foam ceramic filter 3 ceramic foam filters in the foundry industry.

Installing ceramic foam filters to running systems can shield your aluminum castings from unwanted nonmetallic materials.

In excellent shape all over the world.

Whether your foundry produces standard aluminum castings or critical complex thin wall aerospace.

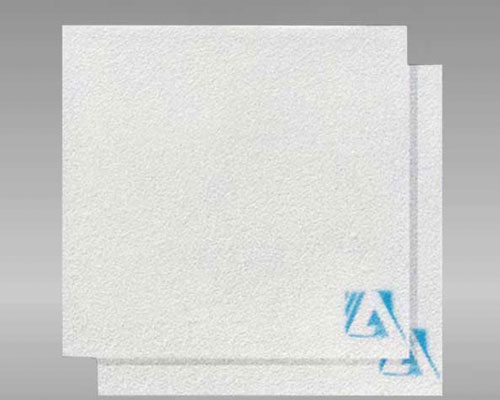

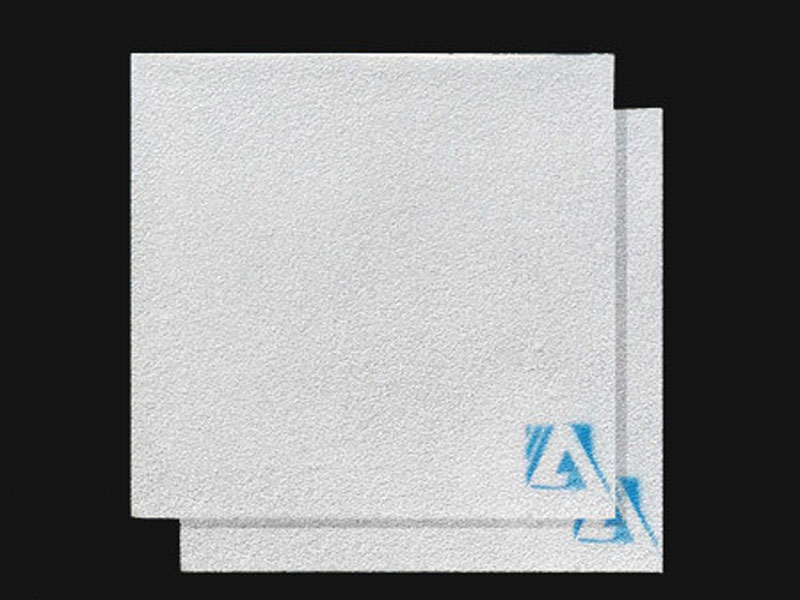

Ceramic foam filters of selee structure are preferred by aluminum foundries of all types and levels of production due to their superior dimensional control.

The udicell tubular foam ceramic filters are perfectly suitable for secure filtering of large quantities of liquid metal and feature a distinctive value added design.

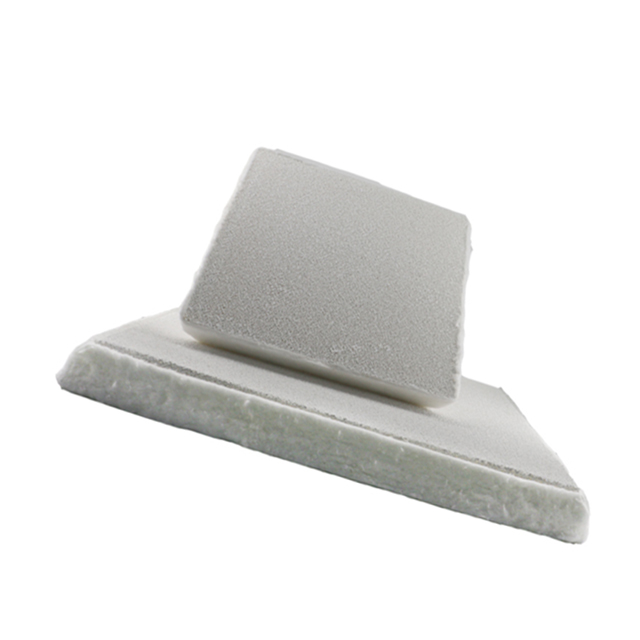

The shapes and dimensions of the filter bag depend on the molding technology and the casting parameters presently there are mainly two different types of bags used in the aluminium metallurgical industry.

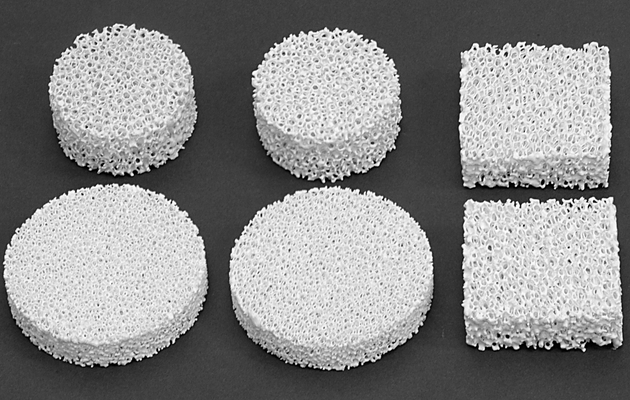

They are manufactured in a range of compositions and sizes to suit the varied processes and equipment used in the aluminum foundry.

Plant for the production of aluminum and cast steel.

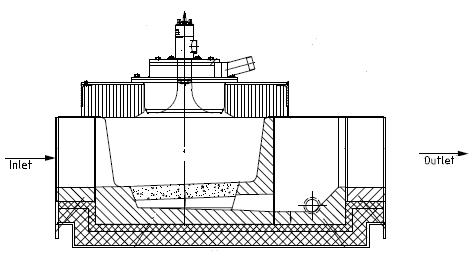

Typical industrial use of a ceramic foam filter in a filter box which is installed in the metal transfer line from the melting furnace to the dispensing furnace or casting unit shown in the figures 4 and 5.

Foundry molten metal filters ceramic foam filters fiberglass fabrics mesh filters.

Ceramic foam filters cff of selee structure are preferred by aluminum foundries of all types and levels of production due to their superior dimensional control.

Sedex sic ceramic foam filters.

Filters can be used with all types of cast irons aluminum and copper based alloys and are available in a broad range of sizes shapes and performance levels.

Sedex is a range of silicon carbide based ceramic foam filters designed for use in grey and ductile iron applications to provide a smooth laminar flow of molten metal and prevent the ingress of slag magnesium reaction products inoculant residues or sand grains into the mould cavity the maximum application temperature for sedex filters is 1500 c.

Alumina ceramic foam filter is mainly for the filtration of molten aluminium and alloys in foundries and.

Drache ceramic foam filters and refractory components.

They are manufactured in a range of shapes and sizes to suit the varied processes and equipment used in the aluminum foundry.

Innovative products for the foundry industry.

The advantages of this design include more than three times the filter area compared to a conventional plate shaped filter of the same size a self supporting geometry a.