The hybrid ceramic ball bearings market is projected to grow with a cagr of xx during the forecast period.

Ceramic hybrid ball bearing research paper.

The recently published hybrid ceramic ball bearings market research report offers an unabridged assessment of this industry vertical with respect to the key growth catalysts challenges and opportunities affecting the business expansion.

Component material ball roller slicion nitride hipsn rings x102 crmo 17 x30 crmo v 15 2 x40 crmovn 16 2 hss 6 5 2.

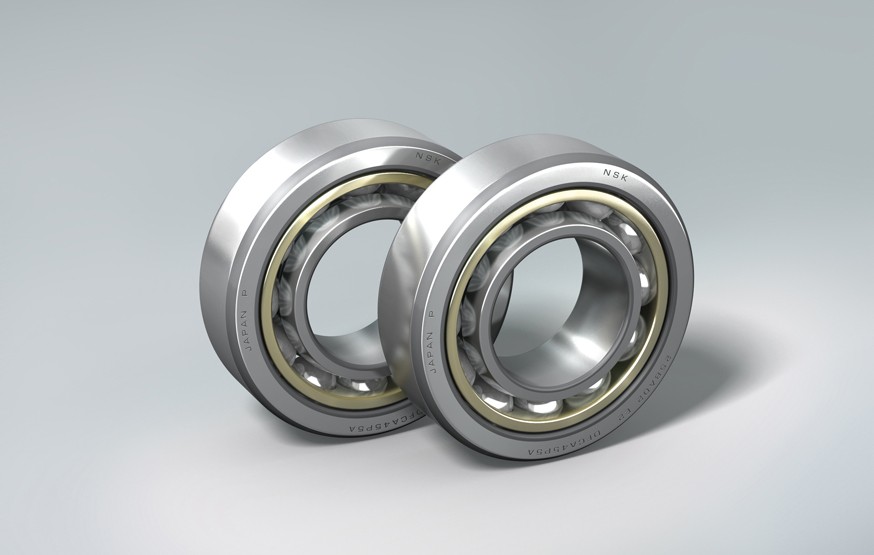

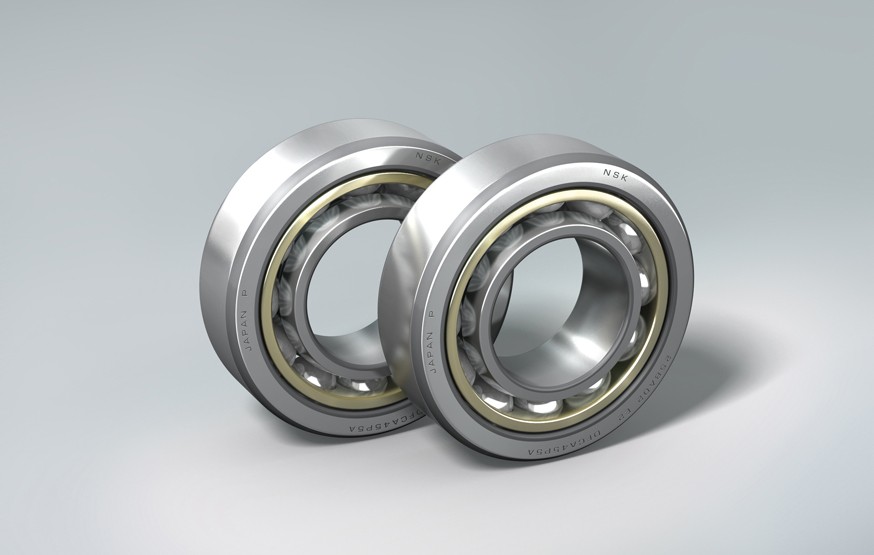

In addition to being excellent electric insulators hybrid bearings have a higher speed capability and will provide longer service life than all steel bearings in most applications.

Mrc hybrid ceramic ball bearings use a combination of traditional 52100 steel rings precision matched with silicon nitride ceramic balls.

In addition to being excellent electric insulators hybrid bearings have a higher speed capability 1 2 1 5 time limit of rotations compared to steel bearing and will provide longer service life lower friction and a lower level of energy consumption than all steel bearings.

Hybrid bearings have rings made of bearing steel and rolling elements made of bearing grade silicon nitride si 3 n 4 which make the bearings electrically insulating.

Material of bearing ccomponents in advanced hybrid ceramic bearings.

A key for this is the combination of corrosion resistant steels with si3n4 table 1.

This paper presents a high speed high precision spindle system with hybrid ceramic bearing along with its lubricant design and numerical calculation method.

Hybrid ceramic bearings have traditional 52100 steel or stainless steel rings with ceramic silicon nitride si3n4 balls.

Silicon nitride rolling elements can extend bearing service life by offering enhanced bearing performance even under difficult operating conditions.