During moulding the feedstock plasticizes and is injected with high pressure into the cavity.

Ceramic injection molding process.

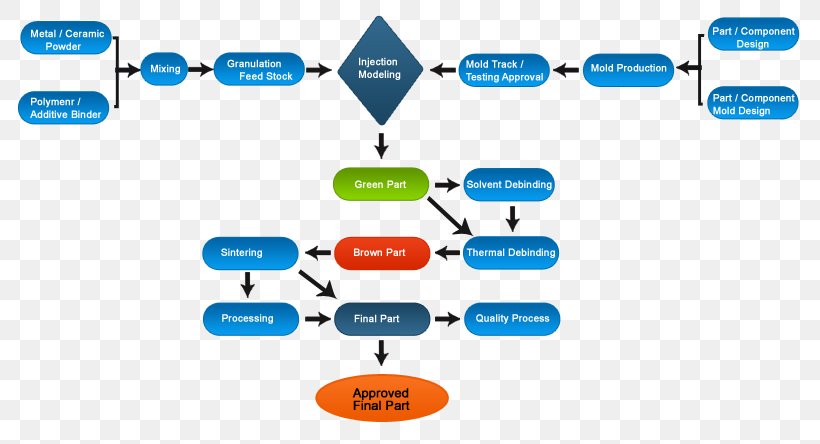

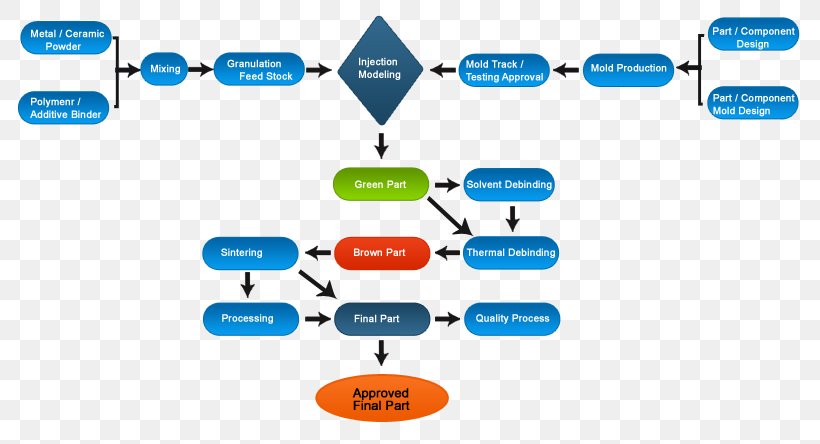

Feedstock preparation injection molding debinding process and sintering fig.

Process flow for capillary manufacturing process stage 1.

The mim cycle begins with preparation of a feedstock by mixing fine metallic powder with a binder comprising waxes polymers lubricants and surfactants.

The first step in cim begins with very fine ceramic powders which are compounded with polymer binders into a feedstock.

It is an effective way of manufacturing complex precision components with the highest degree of repeatability and reproducibility.

Using sophisticated mixing technology the powders are compounded with thermoplastic binders to produce a homogeneous pelletised feedstock.

Ceramic injection molding is ideal for high volume production of complex tight tolerance components.

The cim process gives production engineers and product designers more versatility in the use of ceramics as an alternative material with higher productivity lower manufacturing costs and improved product performance.

The binders form a liquid medium which carries the ceramic powders into the mould during the injection stage.

The ceramic injection molding process consists of four basic steps.

In another branch of pim ceramic or carbide materials are used as raw materials in a process called ceramic injection moulding cim.

Ceramic injection moulding process after deciding which ceramic you want to have for your application the cim process is as follows.

The ceramic injection molding is very suitable for high volume production of complex design with tight tolerances like bonding capillaries.

Injection molded ceramics brochure injection molding eliminates the need for secondary operations normally required to produce complex geometrical shapes.

Ceramic injection molding is an innovative new process at indo mim under a six sigma controlled environment.

The resulting feedstock is then granulated.